Bridging the gap between machined and injection moulded parts, 3D printers have transformed the way industry works. The ability to produce three dimensional solid objects from a 3D digital file has become a mainstream manufacturing process with extensive benefits for the automated materials handling market.

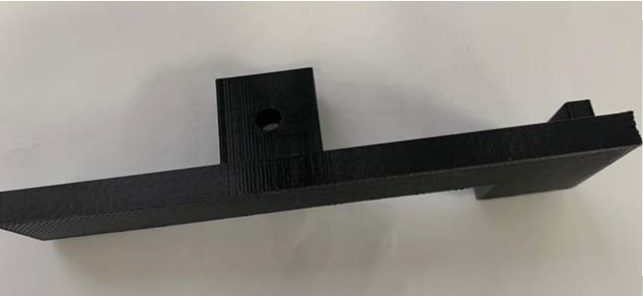

Keeping ahead of the competition, Axiom GB has recently invested in four high-tech 3D printers to ensure that its customers can make the most of the many manufacturing advances offered by this printing technique.

From low cost printing of small production runs to rapid prototyping, in-house fabrication at Axiom has taken a giant step forward.

Advantages of 3D printing

Production on demand – supply meets demand. Components are quickly and easily made in-house as and when they are required.

Freedom to customise – this type of manufacture is ideal for building single parts or one-off products which can be designed to meet an individual project. Complex components can be produced that would either impossible or very expensive by conventional methods.

Wide range of raw materials – the component is developed through the successive layering of material – this could be a diverse range of materials from plastics to glass, ceramics or metal.

Quality and consistency – each product is individually manufactured in a step by step process to precise measurements.

Rapid prototyping – products can be designed as a CAD model and then transformed rapidly into functional prototypes in the space of a few short hours ready for testing. This type of one step manufacture would have been unthinkable without 3D printing – it would take weeks if not months to go from design to prototype stage.

Cost effective – low labour costs – an operator is required to set up and start the machine and thereafter the process can be supervised remotely over networks. Parts are produced on site which results in less shipping time and cost. There is no overproduction and therefore reduced storage costs.

Accessibility – one machine can accomplish a task which previously would have taken a whole range of production processes.

Sustainability – there is very little waste. 3D printing uses only sufficient raw material to create the shape required making it a very sustainable way to manufacture parts.

Customer Advantage

Matthew Nickson, director of Axiom GB comments “There is no doubt that the advent of 3D printing is having a significant effect on the automation industry. It is an extremely valuable resource for the production of low volume, customer-specific items which can be produced cost effectively on demand.

“Our capability to manufacture both simple and very complex parts in-house is extremely advantageous to our customers. Production is 24/7 and entirely under our control – we are not dependent on deliveries from suppliers.

“Customers will also benefit from 3D printing’s rapid prototyping process – transforming the time it takes to design, manufacture and test a customised component. This capability ensures that Axiom continues to be a leading light in the design and manufacture of automation equipment.”

Axiom GB continues to innovate and excel in the automation processes. If you would like to talk to an experienced team you can trust, contact one of the engineers for a consultation on +44 1827 61212 or email sales@axiomgb.com